Understanding Concrete Grinding in Birmingham and Its Benefits

Concrete grinding has become an essential process for property owners, contractors, and facility managers in Birmingham seeking durable, aesthetically pleasing, and functional floors. As Birmingham continues to grow as a commercial, industrial, and residential hub, the demand for high-quality concrete flooring solutions has surged. Whether you’re refurbishing an existing floor or installing a new one, understanding the intricacies of concrete grinding can significantly enhance your project outcomes. For those in Birmingham looking to ensure their floors are precisely finished, Concrete grinding Birmingham offers expert services backed by industry standards and innovative techniques.

What is concrete grinding and why it matters

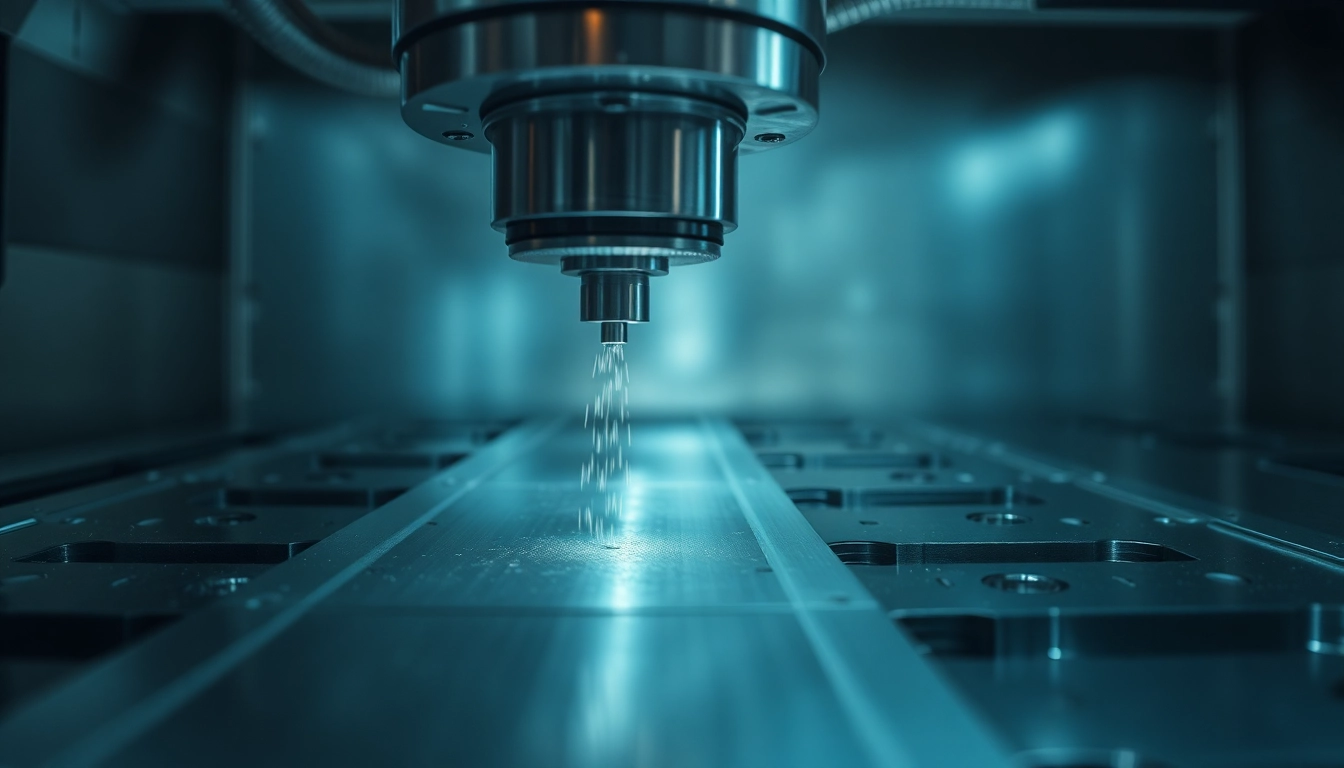

Concrete grinding is a process that involves using specialized machinery to smooth, level, and prepare concrete surfaces. It entails removing unevenness, old coatings, stains, or surface imperfections to achieve a clean, flat finish. This process not only enhances the appearance but also prepares the floor for further treatments such as polishing, sealing, or coating. In Birmingham, where many commercial properties and industrial facilities require resilient floors capable of withstanding heavy use, concrete grinding serves as a critical preparatory step.

Moreover, concrete grinding can improve safety by eliminating trip hazards and reducing dust accumulation. It also contributes to the longevity of flooring investments by creating an even surface that resists cracking, spalling, or other forms of deterioration.

Advantages of professional concrete grinding services

Choosing professional concrete grinding provides multiple benefits that DIY methods often cannot match. These advantages include:

- Superior Finish Quality: Experts use precision equipment and techniques to produce a level, smooth surface that meets your specifications.

- Time Efficiency: Trained professionals complete projects more quickly, minimizing disruption to your operations.

- Enhanced Durability: Proper grinding extends the lifespan of your concrete floors by removing weak or damaged layers.

- Customization Options: Professionals tailor the grinding process to suit specific needs, whether for polishing, texture, or surface preparation.

- Safety Compliance: Certified operators follow strict safety protocols, protecting both workers and property.

In Birmingham, local providers are equipped with state-of-the-art machinery and up-to-date industry knowledge, ensuring optimal results for every project.

Common applications of concrete grinding in Birmingham projects

Concrete grinding finds applications across various sectors in Birmingham, including:

- Commercial Floors: Retail outlets, office complexes, and malls utilize grinding to prepare floors for polishing and coatings.

- Industrial Facilities: Factories, warehouses, and manufacturing plants benefit from heavy-duty grinding to produce durable and safe surfaces.

- Residential Properties: Homeowners seek grinding during basement conversions, garage flooring, or basement remodeling projects.

- Public Infrastructure: Hospitals, schools, and government buildings require high-standards for safety and aesthetics, supported by precise grinding processes.

For instance, Birmingham’s growing industrial parks often employ grinding to prepare concrete surfaces for sealing and finishing, ensuring they withstand heavy machinery and foot traffic.

Choosing the Right Concrete Grinding Solutions for Your Property

Different types of grinding techniques and their features

Understanding various grinding techniques allows property owners to select the most appropriate method for their needs:

- Uses coarse abrasives to remove imperfections, paint, or adhesives, providing a clean surface suited for overlaying or sealing.

- Leveling Grinding: Involves finer abrasives to correct uneven surfaces and promote a flawless, level finish, critical for commercial floors.

- Polishing Grinding: Utilizes progressively finer diamond abrasives to achieve a glossy, mirror-like finish that enhances aesthetics and durability.

- Overlay or Resurfacing Grinding: Combines grinding with overlay techniques to restore worn or damaged concrete without complete replacement.

Choosing the right technique hinges on the current state of your concrete, desired finish, and long-term usage requirements.

Factors to consider when selecting a concrete grinding provider

When choosing a contractor in Birmingham, consider the following criteria:

- Experience and Reputation: Look for companies with proven track records and positive reviews from local clients.

- Certification and Safety Standards: Ensure your provider complies with industry safety protocols and holds relevant certifications.

- Equipment Quality: Advanced machinery, such as planetary grinders and dust extraction systems, ensure efficient and clean operations.

- Customization Capability: A flexible provider can adapt their techniques to your specific project needs.

- Turnaround Time and Cost: Balance your timeline constraints with budget considerations to select a reliable partner.

How to assess quality and durability of finished floors

Post-project evaluation is crucial to ensure your concrete floor meets expectations. Key indicators include:

- Flatness and Levelness: The floor should be even without noticeable bumps or dips.

- Surface Integrity: No visible cracks, spalling, or surface delamination.

- Aesthetic Finish: Uniform shine, color consistency, and smoothness, especially for polished finishes.

- Adhesion of Coatings: Any sealers or overlays should adhere firmly without peeling.

- Functional Performance: The floor withstands intended load and foot traffic without deterioration.

Regular inspections and appropriate maintenance can sustain these qualities over time.

Best Practices and Industry Standards in Birmingham Concrete Grinding

Safety protocols and equipment standards

Safety is paramount in concrete grinding operations. Professionals adhere to standards such as OSHA regulations, utilizing PPE like respirators, eye protection, gloves, and hearing guards. Equipment must be well-maintained, with dust extraction systems preventing airborne particulates, which is vital in Birmingham’s urban environment.

Preparing your site for effective grinding results

Proper site preparation includes removing obstructions, covering sensitive objects, and ensuring adequate lighting and ventilation. Clear communication with your contractor ensures that work proceeds smoothly, avoiding delays and rework.

Post-grinding sealing and finishing for longevity

Applying sealers or protective coatings after grinding enhances resistance to stains, wear, and chemicals. Regular resealing, depending on floor usage, maintains the surface’s integrity and appearance.

Implementation Steps for Successful Concrete Grinding Projects

Initial assessment and planning phase

Start with a thorough evaluation of the existing surface, identifying issues such as cracks, stains, or unevenness. Collaborate with your contractor to determine the appropriate grinding techniques, timeline, and budget.

Executing the grinding process efficiently

Professional technicians use calibrated equipment to perform systematic grinding passes, progressively using finer abrasives to achieve the desired finish. Maintaining dust control and safety throughout is essential.

Ensuring quality control and final inspection

Upon completing the grind, inspect the surface for flatness, cleanliness, and any defects. Address any issues immediately to ensure optimal results before applying finishes or coatings.

Measuring Performance and Maintaining Your Concrete Floors

Indicators of a well-executed grinding job

A successful project is marked by a uniformly smooth surface, strong adhesion of coatings, and the absence of surface defects. Customer feedback and visual inspections often serve as initial quality indicators.

Regular maintenance tips for durable polished concrete

Maintain polished floors by routine cleaning using non-abrasive, pH-neutral cleaners, and promptly addressing spills or stains. Periodic re-polishing or sealing can restore luster and durability.

When to consider resurfacing or additional treatments

Persistent cracks, surface wear, or staining may necessitate further grinding, resurfacing, or recoating. Regular assessments can help catch issues early, minimizing repair costs and preserving the floor’s integrity.